What You’ll Learn 🧭

Understand various angle sensors: inductive (LVDT/RVDT), tacho probes (analogue/digital), encoders, gear‑tooth sensors (with/without zero pulse), optical sensors, gyros, and tape sensors

Recognize key sensor characteristics: output type, resolution (X1/X2/X4 modes), supply requirements, sensing range, and environmental specs

Learn proper mounting techniques, input filtering to suppress noise/glitches, and encoder configuration for optimal signal integrity

Use SuperCounter® counter inputs for nanosecond-precision timing and synchronized analog-digital capture

Configure Angle Sensor math in DewesoftX: set sensor type, pulses per revolution, zero offset; produce angle & frequency output channels – includes handling cold-start delays

Apply angle & frequency measurement in real applications: steering wheel angles, wheel speed, shaft rotation, and converting time-domain signals into angle-domain for advanced analysis

Integrate angle data into modules like Torsional Vibration, Order Tracking, or Power/Phase analysis using synchronized measurement tools

Course overview

The course equips engineers with the knowledge to measure and analyze precise angular positions and rotational speed using DewesoftX. Start by exploring different sensor technologies—like RVDT/LVDT, tacho probes, gear‑tooth wheels, and optical encoders—learning their wiring, output types, and environmental behavior.

You’ll then dive into practical setup: placing encoders or tacho probes correctly, selecting the appropriate X-mode resolution (X1/X2/X4), applying input filtering to reduce spurious pulses, and leveraging SuperCounter® input timing resolution for synchronized analog/digital acquisition.

Using DewesoftX’s Angle Sensor math module, you’ll define sensor types, pulses per revolution, encoder direction, and zero-pulse offsets. The module autonomously handles initialization delays (e.g., first gap detection) and outputs continuous angle and RPM/frequency channels.

The course also highlights real-world use cases—such as steering wheel positioning, wheel-speed tracking, and shaft rotation monitoring—while demonstrating how to convert time-based data into the angle domain for advanced analysis workflows . The resulting angle and frequency channels can then feed higher-level analysis modules like torsional vibration, order tracking, or phase-aligned power/vector diagrams.

By the end, you’ll be able to set up and calibrate angular sensor measurements accurately within DewesoftX, ensuring high-resolution and synchronized data capture for mechanical controls, drivetrain diagnostics, and dynamic system testing.

What is angular position sensor?

An angular position sensor measures the position of a shaft and converts it into either an analog or a digital signal. It determines the orientation of an object relative to a specified reference position.

There are many different types of angular position sensors, categorized by supply voltage, output type, sensing range, operating temperature range, packaging type, and supply current.

Angular position sensors are widely used in both automotive and industrial applications, including:

Steering wheel position sensing

Pedal position sensing

Throttle position sensing

Torque sensing

When selecting the right angular position sensor, it is important to carefully match the sensor to the specific application requirements, such as:

Output type (analog or digital output)

Sensing range (±500°/s, ±100°/s, ±60°/s, 360°/s)

Supply current (from 100 µA to 13.5 A)

What types of angle sensors do we know?

An angular position sensor measures the angular position of a shaft. Angle sensors can be of different types, depending on the application.

Inductive sensors

Optical probes

Encoders

Gear tooth with missing teeth

You can connect the following types of sensors to Dewesoft software and hardware:

| Sensor | Analog | Digital |

|---|---|---|

| Encoder | ✗ (relative, absolute is not supported) | ✓ |

| Tacho | ✓ | ✓ |

| Geartooth CMD | ✗ | ✓ |

| Geartooth with zero | ✗ | ✓ |

| Geartooth with missing teeth | ✓ | ✗ |

| Geartooth with double teeth | ✓ (x-n type sensors) | ✗ |

| Linear Encoder | ✗ | ✓ |

| Linear pulses Encoder | ✗ | ✓ |

| Tape sensor | ✗ | ✓ |

When measuring angles, it is critical to select the appropriate sensor to ensure accurate results.

| Advantages | Disadvantages | |

|---|---|---|

| Encoder | best resolution | critical mounting |

| useful for low RPMs | ||

| Tacho sensor | easy installation | bad resolution |

| cheap | not useful for TV and CA | |

| Tape sensor | easy installation | expensive |

| good resolution | ||

| zero position | ||

| CA-RIE encoder | best for high RPM vibrations | extensive installation |

What is rotary variable differential transformer?

A Rotary Variable Differential Transformer (RVDT) is an angular position sensor that produces an output voltage proportional to angular displacement.

When the rotor is positioned so that the available flux is directed equally into both the in-phase and out-of-phase coils, the output voltages cancel each other out, resulting in a zero-value signal. This is referred to as the electrical zero position. When the rotor shaft is displaced from this position, the output signals vary in magnitude and phase in proportion to the direction of rotation. Because RVDTs operate essentially like transformers, changes in excitation voltage cause proportional changes in the output (transformation ratio). However, the ratio of output voltage to excitation voltage remains constant.

The basic construction and operation of an RVDT involve an iron core, mounted on bearings, that rotates within a housed stator. The stator consists of a primary excitation coil and a pair of secondary output coils. A fixed alternating current excitation is applied to the primary coil, which is electromagnetically coupled to the secondary coils. This coupling is proportional to the angle of the input shaft. The secondary coil pair is arranged so that one is in-phase with the excitation coil, while the other is 180 degrees out of phase.

What is MSI - LVDT adapter?

The MSI-LVDT adapter is a complete Linear Variable Differential Transformer (LVDT) signal-conditioning subsystem. It is used in conjunction with LVDTs to convert a transducer’s mechanical position into a unipolar DC voltage with a high degree of accuracy and repeatability.

An LVDT converts position or linear displacement from a mechanical reference point (zero or null position) into a proportional electrical signal that carries both phase information (indicating direction) and amplitude information (indicating distance). LVDTs do not require electrical contact between the moving part (probe or core assembly) and the coil assembly; instead, they rely on electromagnetic coupling.

The adapter generates 4 or 10 kHz excitation to connect with LVDT sensors and provides phase adjustment through a potentiometer, where an output of 1 V corresponds to 1000 mV/V. It also includes automatic adapter identification.

Functional block diagram of MSI - LVDT

The MSI-LVDT adapter uses a unique ratiometric architecture to eliminate several disadvantages associated with traditional approaches to LVDT interfacing. The benefits of this new circuit include: no required adjustments, improved temperature stability, and better transducer interchangeability.

Technical data of MSI - LVDT

The MSI-LVDT adapter is powered by an EXC voltage. It is compatible with SIRIUS(i) instruments (variable EXC) or the DEWE-43A instrument (fixed ±5 V EXC).

Operation of MSI - LVDT

To use, connect the LVDT adapter to your SIRIUS or DEWE-43 channel, and then connect the sensor probe to the SENSOR input.

Depending on the sensor used, select the excitation frequency of the adapter as close as possible to the required value.

With phase compensation, you can adjust the measured output to achieve the maximum output value.

MSI adapters / TEDS sensor support

Since the adapter itself has a built-in TEDS device, if MSI Adapters/TEDS Sensors are selected under Hardware Setup, the adapter will be recognized automatically and the proper excitation voltage will be applied.

Please ensure that you are using the latest version of the software that supports the LVDT Adapter.

The MSI-LVDT adapter is recognized and configured automatically.

Manual settings

If MSI Adapters/TEDS Sensors are left unchecked in the Devices settings, then the sensor supply and range must be set manually.

Under Channel Setup for channel N, set the Excitation Voltage between 10 V and 15 V maximum, as shown in Image 13.

What is Tacho sensor?

A tachometer is a sensor device used to measure the rotational speed of an object, such as the engine shaft in a car. It indicates the number of revolutions per minute (RPM) performed by the object.

Types of Tachometers

Digital tachometers – These feature an LCD or LED readout with memory for storage. They can perform statistical operations and are well-suited for precision measurement and monitoring of time-based quantities. Digital tachometers are widely used today because they provide direct numerical readings rather than using dials and needles.

Contact and non-contact tachometers – The contact type requires physical contact with the rotating shaft, typically using an optical encoder or magnetic sensor. The non-contact type, ideal for mobile applications, uses a laser or an optical disk.

Time and frequency measuring tachometers – These operate based on different measurement methods:

Time measuring devices calculate speed by measuring the time interval between incoming pulses. They are best suited for low-speed measurements.

Frequency measuring devices calculate speed by measuring the frequency of incoming pulses. They are ideal for high-speed measurements.

Working principle and applications

The working principle of an electronic tachometer is straightforward. The system generates a voltage pulse at the output of the tachometer’s electromechanical part. The electromechanical part responds to the average voltage of the pulse train, which is proportional to the rotational speed. The signal from the sensor head is transmitted via a standard twin-screened cable to the indicator.

Tachometers are temperature-compensated to ensure reliable operation within an ambient temperature range of -10 °C to +70 °C.

Key Applications

Automotive – Used to monitor the speed of mechanical devices in RPM. In automobiles, tachometers monitor engine RPMs to prevent excessive speeds that can shorten engine life.

Aviation – Airplanes typically have one tachometer for each engine. Propeller-driven aircraft require additional tachometers, one for each propeller. In aircraft with gas turbines, at least two sensors are used: one for the inner high-pressure combustion shaft and another for the outer low-pressure air intake shaft. Since engines usually operate at higher RPMs than propellers, separate instruments allow pilots and crew to detect issues with specific components.

Dewesoft tacho sensors

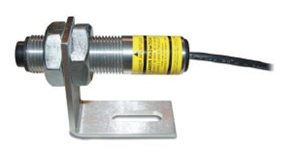

DS-TACHO2 – Optical Tacho Probe with LED

Stainless steel housing with 2.5 m cable

Frequency range: up to 4 kHz

Measurement distance: up to 1 m

Power supply: 3–15 VDC, 45 mA

Visible red pointer with control LED

Operating temperature: -10 °C to +70 °C

Dimensions: 73 mm (length), 16 mm (diameter)

L1B7 connector for SIRIUS and DEWE-43 counter inputs

Includes 30 cm reflector band

DS-TACHO3

Optical Tacho probe with LASER (red class 2)

Stainless steel housing with 2.5 m cable

Frequency range: up to 4 kHz

Measurement distance: up to 7.5 m

Power supply: 3–15 VDC, 0.13 W

Visible red laser pointer

Control LED

Operating temperature: -10 °C to +70 °C

Dimensions: 73 mm (length), 16 mm (diameter)

L1B7 connector for SIRIUS and DEWE-43 counter inputs

Includes 30 cm reflector band

DS-TACHO4

Optical Tacho probe with LASER (red class 2)

Equipped with 5 m optical fiber and trigger box

Frequency range: up to 100 kHz

Measurement distance: 2–5 mm

Power supply: 3–30 VDC, 120 mA

Operating temperature: -10 °C to +70 °C

Dimensions: M6 × 20 mm sensor head, 2.5 m cable

L1B7 connector for SIRIUS and DEWE-43 counter inputs

Includes 1 m reflector band with 2 mm black/white grid

Measurement example with tachometer

The measurement example was made using a tacho probe mounted on the rotating shaft of a machine. In the picture below, we can see the signal from the tacho, where one spike corresponds to each rotation of the shaft..

With the Angle Sensor math function in DewesoftX, we can calculate the exact frequency and angle from this signal. The input to the math channel was the signal from the tacho (type: Tacho (Digital)). Referring to the picture above, we can properly set the trigger and retrigger levels.

In Measure mode, we add a digital meter to display the frequency of rotations. The frequency can also be observed using cursor values, provided that Cursor I and Cursor II are set up correctly.

What is DS-TACHO1?

DS-TACHO1 is a tacho adapter that converts an analog tacho signal to a Dewesoft instrument’s CNT/DI input (Lemo 7-pin) with an adjustable trigger level (TTL logic signal). It fits into the COUNTER input (Lemo 7-pin) on DEWE-43 and SIRIUS ±100 V input. The trigger threshold is adjustable from ±10 mV to ±2 V.

Tacho Adapter Electronic Specifications Table:

| Trigger / Retrigger level | ±10 mV ... ±2 V (adjustable with screwdriver) |

| Input type | AC - Coupled, 1 Hz |

| Input impedance | 150 kOhm |

| Max input voltage | ±50 VDC, ±100 VAC |

| Power supply output | ±5 VDC (max current depending on used Dewesoft device: for example DEWE-43: max 800 mA) |

How does it work?

Connect the DS-TACHO1 with the LEMO 7-pin connector to a DEWE-43 or SIRIUS counter input, and on the DSUB 9-pin side to your analog tacho probe signal (e.g., a magnetic pickup sensor with a screw, providing 1 pulse per revolution).

Start the rotating machine, then use a screwdriver to manually adjust the trigger level on the DS-TACHO1 (see picture below).

When the trigger is correctly detected, the blue LED will flash. Vary the RPM of the machine to check if the trigger level is appropriate for the entire RPM range.

The lowest detectable frequency for the counter input on the DEWE-43/SIRIUS is 5 Hz. Therefore, if you have 1 pulse per revolution, the lowest measurable RPM is 300. If you need to measure lower RPM, you can increase the number of pulses per revolution (e.g., for an inductive probe, mount a screw every 90° on the rotating disk and then divide the result by 4).

In this example, you can see the input signal of a magnetic tacho probe (coil) when a screw on the disk passes by. The higher the RPM, the higher the induced voltage. Therefore, the trigger level must be set low (shown in the picture at ±10 mV).

The upper red line represents the trigger level, while the lower orange line represents the retrigger level. The signal must fall below the lower line to be re-armed for the next trigger. This setup even makes it possible to correctly detect poor-quality signals, as shown above.

What is gear tooth angle sensor?

The sensing distance between the sensor and the gear tooth is influenced by many factors, including the gear tooth dimensions, the grade of ferrous metal used in the gear, and the alignment of the sensor with the gear. Typically, larger teeth and wider slots allow for a greater sensing air gap. For best performance, the sensor should be positioned as close as possible to the target.

Hall effect gear tooth sensing uses a Hall element to detect variations in magnetic flux within the air gap between a magnet and the passing ferrous gear teeth. A modern approach involves converting the Hall element’s signal into a digital value, followed by signal processing to generate a digital output. When the signal level changes beyond a preset magnitude—whether from the positive or negative peak—the output level is updated. This creates a digital zero-speed peak detection sensor that is immune to orientation requirements and can track gear speed down to a complete stop. It will also detect the first edge of the next tooth immediately after power-on.

However, digital signal processing introduces a quantization uncertainty, which increases at higher speeds. As a result, extremely demanding timing applications, such as those in crank position sensors, may experience reduced accuracy at high rotational speeds.

To detect passing gear teeth with a Hall effect sensor, a source of magnetic energy is required. The simplest way to achieve this is by placing a permanent magnet so that its axis of magnetization points toward the surface of the gear teeth. As a tooth moves across the magnet’s surface, the magnetic flux is drawn to the lower reluctance path created by the ferrous steel structure. When this happens, the flux density measured by the Hall element between the sensor face and the gear tooth increases.

60-2 angle sensor

The term 60-2 angle sensor refers to a crank trigger wheel with 58 teeth and 2 missing teeth. This configuration is also commonly known as a 58-tooth wheel.

The missing teeth are used as reference markers, allowing the sensor to recognize the exact angular position of the crankshaft. With 58 teeth, the sensor provides a more precise calculation of engine speed compared to a trigger wheel with fewer teeth.

Measurement with 60-2 angle sensor

In the example below, we can see the signal generated by a 60-2 angle sensor. The two missing teeth are clearly identifiable, and they are used to determine the crankshaft’s zero position.

A zoomed-in view of the 60-2 angle sensor signal looks like this:

What is gyro sensor?

Gyro sensors are angular velocity sensors that detect rotational motion and changes in orientation. Angular velocity is defined as the change in rotational angle per unit of time and is expressed in degrees per second (°/s).

Types of Gyro sensors

Ring laser gyros – used in space shuttles and aircraft

Fiber-optic gyros – used in motorboats, race cars, and robot balance control

Fluid gyros – used in radio-controlled helicopters and motion sensors

Vibration gyros – used in car navigation, mobile games, and digital cameras. Miniature, high-accuracy vibration gyro sensors are indispensable.

Vibration Gyro sensor

Vibration gyro sensors can detect angular velocity based on the Coriolis force, which acts on a vibrating element. This force produces a potential difference that is used to measure angular velocity. The measured angular velocity is then converted into an electrical signal output.

Manufacturers use a variety of materials and structures to design compact, high-accuracy gyro sensors with the following key characteristics:

Scale factor

Shock resistance

Stability

Working principle

The drive arm vibrates in a fixed direction.

The drive arm vibrates in the direction of rotation.

When the gyro rotates, the Coriolis force acts on the drive arm, generating vertical vibrations.

The stationary part bends due to the vertical movement of the drive arm, producing a sensing motion in the sensing arm.

The motion of the pair of sensing arms generates a potential difference, which is used to detect angular velocity. This angular velocity is then converted into an electrical signal.

Gyro sensor applications

The main applications for gyro sensors are:

Angular velocity sensing – Detecting the amount of angular velocity generated, which corresponds to the motion itself (e.g., sensing athletic movement).

Angle sensing – Measuring angular velocity produced by the sensor’s own movement. Angles are calculated by a CPU, and the detected angle is then applied in various applications such as car navigation systems, video game controllers, and mobile phones.

Control mechanisms – Detecting vibrations caused by external factors. This vibration data is converted into electrical signals and transmitted to a CPU, which uses the information to correct the balance or orientation of an object.

What is optical angle sensor?

Optical sensors are electronic detectors that convert light, or changes in light, into an electronic signal. A rugged industrial encoder is an optical sensor that operates on the light transmission principle. The encoder is mounted between the engine and the brake shaft. An infrared beam is emitted and received by the sensor unit, with a customized marker disk positioned between the sensor’s gate. The slits on the disk interrupt the infrared beam, and the receiver converts the detected light into a voltage signal.

The greater the number of slits, the higher the resolution:

360 slits = 1° resolution (outer diameter 120 mm)

720 slits = 0.5° resolution (outer diameter 230 mm)

Using fiber-optic sensor for angular displacement measurement

The measurement of angular displacement is crucial in many fields. For example, in industry it is used to control the steering of cars, the kinematics of robot arms, and the tilt angles of aircraft. Such measurements can also be integrated into precision rotation stages to control the angular positioning of optical and/or mechanical components.

Another approach to measuring angular displacement is through optical systems using the triangulation method. This method relies on light that is transmitted or reflected by a mirror. In the case of miniaturized sensors, these devices can be fabricated using conventional or silicon-based microfabrication techniques. Fiber-optic sensors provide an additional advantage by significantly reducing the size of the part of the sensor that interacts with the mechanical system.

What is encoder?

An encoder is essentially a wheel (or a linear bar) with markings on it. Typically, encoders have two marks (A and B) with a phase difference of 90 degrees between them, which allows for the determination of the direction of movement. Some encoders also include an additional zero pulse (Z or ZERO) — a single pulse per revolution that indicates the absolute position of the encoder.

The two signals (A and B) are used to determine the direction of rotation or movement. When input A leads input B, the value is incremented, and when input B leads input A, the value is decremented. The Z or ZERO signal is a single pulse that occurs once during each shaft rotation and can be used to mark the zero position.

There are several encoder modes:

X1 mode – measures only the rising edges of input A.

X2 mode – measures both the rising and falling edges of input A.

X4 mode – measures both the rising and falling edges of inputs A and B.

X2 and X4 modes are particularly useful for slow movements (such as with linear encoders) because they effectively increase the measurement resolution by a factor of two or four.

| Required hardware | DEWE-43, Sirius ACC+, MULTI 15 pin |

| Required software | Any version of Dewesoft X |

| Setup sample rate | At least 1 kHz |

If a fast dynamic measurement (such as torsional vibration) is performed, using X2 or X4 mode can sometimes introduce more errors. This occurs because these modes assume that the gap ratio is exactly 0.5 and that the encoder electronics switch at exactly the same speed between dark and light areas. These assumptions are not always true, which can lead to inaccuracies. The error can be evaluated using period and pulse-width measurements.

To set this up, connect the A signal to SOURCE0, the B signal of the encoder to AUX_CNT0, and the zero pulse to GATE0.

Why an input filter is important?

The Filter is also a very important setting used to prevent double counts and glitches. The filter should be set to react slightly faster than the expected event rate, but slightly slower than the expected frequency of glitches. With a manual switch and a 102.4 MHz base clock, some glitches are to be expected.

The optimal input filter settings are described in the Digital Counters PRO training course (Section: Input Filter).

In Image 43, the red curve shows the digital signal from the switch, while the blue curve shows the counter value. The counter value increases with each transition from low to high.

At some points, we can see that values are counted up even when a glitch occurs (not a real pulse). This happens because the counter detects every glitch in the signal, even those shorter than 20 nanoseconds. To avoid this, we need to use a filter to remove such glitches.

For example, if we set the filter to 500 nanoseconds, it will check whether each pulse remains high for at least that duration. If the condition is met, the counter value is incremented.

How to properly mount the encoder?

Encoders are key components in motion control systems, providing feedback to drives for accurate speed and position control. Specifying an encoder, however, can often seem like a challenging task. Major encoder manufacturers continue to release new series while also maintaining a large portion of their legacy product lines, ensuring availability for customers who prefer long-term reliability. At the same time, the number of options within each encoder series continues to grow.

When it comes to installation, mounting requires the most consideration.

Although the interface and electrical options within each encoder series may appear extensive, these choices ultimately depend on the specific application. When selecting a drive, its specifications will list the appropriate input options that must be supported. Among all considerations, encoder mounting is the most critical factor that defines their use. Choosing the correct mounting method can significantly optimize both the performance and lifespan of the encoder.

Coupling

When a flange or foot-mount encoder is selected, it can be attached to a motor using a coupling and an adapter. A coupling fastens to each shaft with set screws and provides spring or mechanical isolation from shock, vibration, or motor shaft movement. This method is often used when an encoder must be paired with an older, non-standard motor, when a ring or hollow-shaft encoder option does not exist, or when shaft movement is too severe for a standard encoder to handle.

Isolating the encoder through a coupling offers several advantages. This mounting method typically provides electrical isolation from the motor. Without electrical isolation, the encoder may be exposed to noise generated by the high currents supplied to or produced by the motor. Such electrical noise can cause missing pulses, added pulses, or even permanent damage to the encoder.

Mechanical isolation is another key benefit. Flexible couplings can absorb shaft movement, making them suitable for installations on older motors or in applications subject to high shock and vibration.

Coupling misalignment

The disadvantages of using couplings are primarily mechanical in nature. The most significant drawback is the additional length required along the shaft. Coupling an encoder can add up to eighteen centimeters to the motor shaft when accounting for the bracket, the shaft gap within the coupling, and the encoder housing. Coupling also introduces additional installation steps.

During installation, any form of misalignment can lead to undesirable side effects. Most notably, the coupling is subjected to unnecessary stresses, which can eventually cause the material to tear or break.

Finally, misalignment can negatively affect speed feedback. This effect is similar to the output velocity ripple of a driven shaft. Such ripples can cause drives to fault or even result in product damage due to excessive vibration.

Direct mount with tether

Direct mounting with a tether places the encoder directly on the motor shaft. Since the encoder already has bearings, no additional mechanical alignment is required. A rod or sheet-steel tether bolts to the motor face (or any fixed object) to prevent the encoder body from rotating.

Motors are powered by different types of voltage sources, each of which can induce different shaft and bearing currents. To protect both the encoder and motor bearings, the shaft of a direct-mount encoder is typically isolated by a plastic sleeve positioned between the motor and encoder shaft. Encoders that lack this plastic sleeve or insert rely on the motor’s shaft current solution or an additional shaft-grounding accessory.

Choosing the appropriate encoder for a motor is often easier with direct-mount encoders. For ring-kit encoders, the exact specifications of the motor face are required. Slotted tethers allow mounting at different radii from the shaft center, and shaft installation requires no sensor alignment. Once the collar is tightened, the shaft portion of the installation is complete. With spring tethers, sudden shaft movements are absorbed, reducing stress.

Direct-mount encoders typically feature a larger moving shaft surface against the encoder housing. This creates a larger entry area into the electronics compared to coupled encoders. Ring encoders, by contrast, have no shaft entry at all. Encoder manufacturers are continuously developing improvements to address this issue, one of which is the use of labyrinth seals.

Ring mount encoders

Ring-mount encoders consist of at least two main components: the sensor ring and a magnetic wheel. The ring is mounted to the drive or accessory end of the motor and uses pilot dimensions that comply with NEMA or IEC standards. The wheel is then inserted onto the shaft, aligned with the sensor embedded in the ring, and fastened securely in place.

Since the wheel moves inside the ring and is detected by a separately mounted part with no direct mechanical connection, the sensors can be potted together with the electronics. This design offers an improvement over direct-mount encoders, which rely on a series of connectors and shaft gaskets. Encoders of this type are commonly used in the paper industry, where airborne fibers or dust tend to accumulate, or in environments where machine washdowns are required.

Liquids generally have little effect on the magnetic technology typically used in ring encoders. As a result, the encoder’s moving parts can be partially or even fully submerged without performance loss.

Unlike other encoder types, ring encoders do not contain bearings. Instead, an air gap surrounds the wheel within the ring housing. This makes them less susceptible to catastrophic damage caused by momentary shocks, since the shape and preload of bearings are critical for signal quality in coupled or direct-mount encoders. Minor shaft movement during rotation does not create spring forces on bearings or induce fatigue in tethers or couplings. Additionally, ring encoders occupy less shaft space. They mount directly to the motor face, and some models even include a mounting surface on the opposite side for attaching brakes or gearboxes.

The primary concern when installing ring encoders is proper wheel alignment relative to the sensor. Unlike coupled or direct-mount encoders, where the factory ensures alignment, the signal quality here depends entirely on the installer’s accuracy. Although a wheel may appear aligned, it can shift out of position once the shaft begins to move. Therefore, it is critical to ensure the wheel remains centered throughout its radial and axial movement. Different manufacturers provide their own alignment guidelines. When installed correctly and used within the specified environmental conditions, a ring encoder can deliver reliable performance for many years.

X1, X2 and X4 modes

The simple encoder mode can be selected by choosing Event Counting or Basic Encoder Counting. First, let’s set up the encoder.

Signal A is connected to CNT_IN0 and Signal B to CNT_IN1. We set the encoder mode to X1 mode and adjust the Input Filter to match the highest frequency. Scaling is straightforward—simply select counts, revolutions, or degrees from the drop-down menu in the Unit column of the Output Channels section, or enter a custom scale factor.

Now let’s take some measurements. The counter output increases when Signal A leads Signal B and decreases when Signal B leads Signal A. The positive edges of Signal A are used to calculate the counts.

If we choose X2 mode in the setup, the counter will register the rising and falling edges of Signal A. As a result, the resolution is increased by a factor of two. All other settings remain the same.

In X4 mode, the counter registers both the rising and falling edges of Signal A as well as Signal B. This increases the measurement resolution by a factor of four.

What is an encoder with zero pulse?

The zero pulse is used to reset the measurement when a Z pulse is detected. The only required change in the setup is to enable the Encoder Zero checkbox. This resets the counter value to 0 whenever a zero pulse occurs. We also need to specify the number of encoder pulses for internal calculations (360 in this example).

The figure below illustrates the operation. The yellow curve represents the zero signal, while the white curve shows the encoder output. When a pulse is detected on the zero pulse input, the counter value resets to 0.

The next figure shows a zoomed-in region of the recorder. It demonstrates that the encoder resets its value at the zero pulse and then continues counting the rising edges of Signal A.

What is DS-TACHO 4?

The DS-TACHO4 sensor is a threshold sensor. This is especially important in proximity detection mode, which is the most commonly used for rotating applications. The working distance can vary depending on the albedo, shape, and distance of the target. Contrast is also a key parameter—for example, teeth versus no teeth, or black versus white marks.

For encoding applications, the recommended distance is only a few millimeters. Position the probe close to the target to avoid incorrect readings caused by rocking or wobbling of the rotating part (according to Descartes’ optical law). On the other hand, when using reflective tape, distances greater than 100 mm are possible. For optimal results, it is highly recommended to use adhesive encoders.

Several factors may affect detection performance. These include liquid drops on the probe surface, excessive dust buildup, or, more generally, any non-transparent medium for the light source—for instance, a diesel engine sump film (carbon is not transparent in the near-infrared range). The patented concept implemented in these sensors significantly simplifies mounting and setup.

Before taking measurements, it is recommended to perform a detection test, even at low speed, to confirm detection feasibility and determine the required detection distance.

If performing a test is not possible due to technical or mounting constraints, a theoretical method can be applied: fix the probe at a distance approximately equal to the width of the black and white strips to be detected—in any case, do not exceed 4 mm.

Mounting the probe

Ensure that you have all required items at your disposal: the sensor, the probe, and the two hand-pieces for optical fixation.

If the two hand-pieces are mounted on the optical head of the sensor, remove them and set them aside.

Insert the two optical fibers with their respective rivets.

Screw on the first hand-piece and tighten it moderately. A small gap between the rivet head and the optical head is normal.

Remove the two fibers to allow mounting of the second hand-piece.

Verify that both fibers and their rivets are assembled correctly.

When inserting the rubber sleeve, hold both the probe and the sensor simultaneously to avoid damaging the optical fibers at the rivet points.

Adjusting the probes

The operational mode of the sensor can be observed at the end of the optical fiber by a visible light beam (not dangerous). The beam is emitted when the sensor is in 1 mode and not emitted when the sensor is in 0 mode. The sensor operates in the near-infrared wavelength to ensure both detection power and immunity to interference. This also provides an indication of the condition of the optical fiber.

The sensor should be positioned approximately 2 to 5 mm above the tape. A sensitivity potentiometer is available to adjust the trigger level for reliable pulse output.

Begin by setting the potentiometer to its middle position. Bring the probe closer to the target until the indicator LED lights up while pointing at the white mark. Then shift the probe and repeat this process to detect the triggering limits on the black marks of the target. Finally, position the probe at an average distance between the two limits. Repeat the procedure to confirm accurate detection—the setup is then complete.

Automatic gap detection

When applying the black-and-white tape to the rotating shaft, there will be an irregular rasterization at the transition point. This irregularity can be used as the zero pulse to indicate a defined start position. However, it may also cause an RPM drop or spike in the measurement.

A software routine automatically determines the number of pulses per revolution and detects the exact gap length, ensuring robust and high-quality measurement.

Sensor setup

The power supply must be perfectly rectified, filtered, and capable of delivering more than 120 mA at 12 V. This is not an open-collector output sensor but a PNP output type. The 152 G7 can tolerate reverse voltage, although this may alter the signal amplitude. The 152 G7 TTL voltage output is 5 VDC, while the 152 G7 voltage output equals the nominal input voltage minus 1.5 VDC.

When connecting the sensor to the acquisition system, the use of dedicated measurement connectors and matching cables is strongly recommended. Do not extend the cable, as this may affect sensor performance.

To verify that the sensor is powered, check whether a faint red LED glows in the small light channel at the front of the optical head. Alternatively, a digital camera can be used to detect the infrared (IR) light. The brightness of this red light is independent of the potentiometer position.

Sensor plug-in

| V Rating | 12 / 24 Vcc |

| V Minimal | 10 Vcc |

| V Maximal | 30 Vcc |

| Current | 120 mA / 12 Vcc |

Specifications

LEMO connector

Connector type: L1B7f

Physical diagram

For measuring RPM and angle in rotating machines, angle sensors are required. Accurate RPM and angle measurement is essential for applications such as balancing, order tracking, and rotational or torsional vibration analysis.

The choice of RPM sensor should be based on the measurement requirements. Not all sensors can be installed on every rotating system, and installation can sometimes require considerable effort. In addition, the selected sensor must provide sufficient resolution for the intended purpose. For example, a sensor with only one pulse per revolution is not suitable for precise angle measurement.

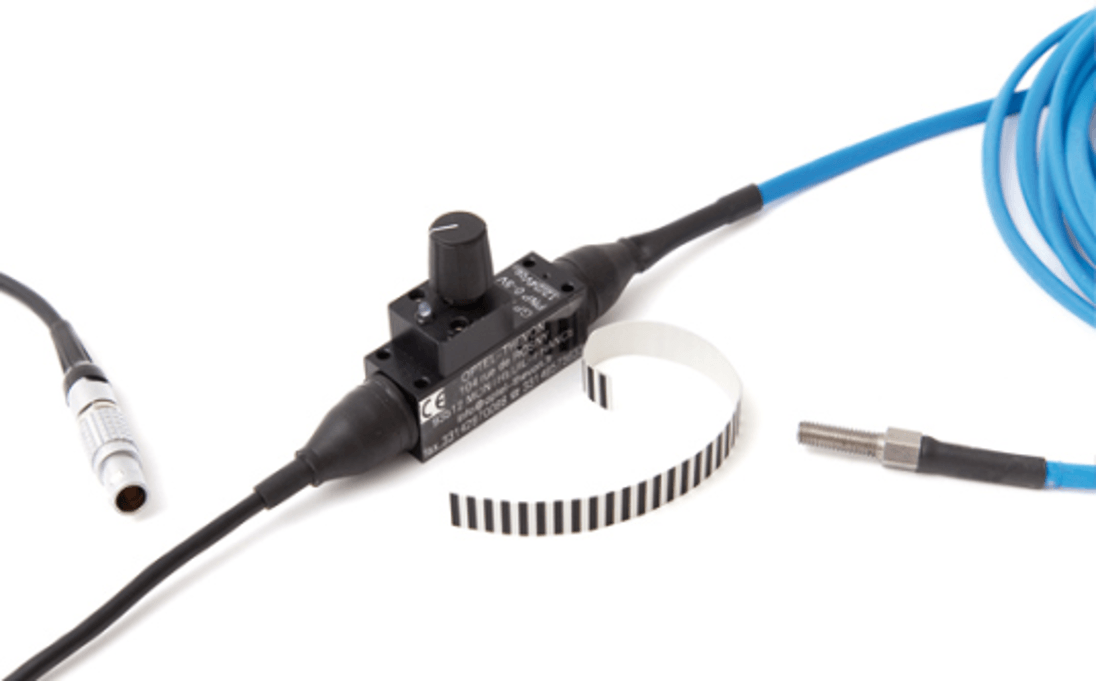

A tape sensor is an optical device used to measure speed and angle. It operates with black-and-white tape that is attached to the rotating part of the machine.

The sensor is made of optical fibers and should be positioned either beneath the tape or approximately 5 mm above it. A sensitivity potentiometer must be used to adjust the trigger level, ensuring steady pulses. The reflected signal is then processed by the internal electronics and converted into a TTL signal. Finally, the sensor is connected directly to a LEMO counter input.

A tape sensor can be used in many applications, including RPM measurement, angle measurement, order tracking, rotor balancing, and rotational or torsional vibration analysis.

Tape sensor setup

First, the tape (with black-and-white stripes) is glued onto the rotating part. If both ends of the tape align perfectly, no zero pulse per revolution will be generated. The zero pulse serves as an indication of the start position. Without this information, the angle would vary with each new measurement.

In the picture above, we can see the transition point of the tape, which is used as the zero pulse. This marks the start of a new revolution, ensuring that the angle measurement always begins at the same position. As a result, angle information relative to the shaft remains consistent.

In the picture below, we can see the frequency drop that occurs at the zero pulse. This drop is clearly visible and can therefore be used to detect the zero pulse. The angle will always start at this position. For the software to reliably detect this drop or peak, the gap length must be greater than three pulses. With this condition met, the software can easily detect the zero pulse, as the frequency decreases by approximately 70%.

The trigger levels must be adjusted to obtain reliable pulses from the optical sensor. This adjustment should be performed after the sensor is mounted, as it depends on the distance to the tape.

Turn the knob fully to the left, then slowly rotate it to the right (clockwise). At first, there will be no output because the sensor is not triggering. With further adjustment, the output will begin.

With further adjustment, the signal quality will gradually improve until the gap becomes clearly visible.

If the adjustment continues beyond this point, the quality will deteriorate again, as shown in Image 72. The correct trigger level lies precisely in between.

The sampling rate must be high enough to detect the frequency drop and clearly identify the gap so that the software can calculate the start and stop of the angle.

Example: Suppose we have 64 pulses per revolution and the machine is running at 1000 rpm.

1000 rpm / 60=16 Hz1000 \, \text{rpm} \,/\, 60 = 16 \, \text{Hz}1000rpm/60=16Hz.

Input frequency = 16 Hz×64 pulses/revolution=1024 Hz16 \, \text{Hz} \times 64 \, \text{pulses/revolution} = 1024 \, \text{Hz}16Hz×64pulses/revolution=1024Hz.

If the sampling rate were set to only 1 kHz, the gap would not be detected on every revolution. To ensure accurate detection, the sampling rate must be at least ten times higher than the maximum input frequency.

Defining sensor type

For RPM measurement, the Sensor Mode must be selected in the Counter setup in DewesoftX.

When Sensor Mode is selected, the sensor can be chosen from the Counter Sensor Database, where different sensor types and their predefined settings are already stored. If a sensor is not yet included in the database, it must be defined manually.

To do this, go to Settings → Counter Sensor Editor, or simply click on the Counter Sensor Editor.

In the Counter Sensor Editor, add a Tape Sensor as the sensor type. In this example, it is renamed to Tape_sensor. When you click Save & Exit, the sensor is added to the Counter Sensor Database and becomes ready for use.

The newly created tape sensor can now be selected from the drop-down menu in the counter channel setup.

For precise measurement, it is necessary to know how many pulses per revolution are generated by the tape sensor and how many pulses are contained in the gap width. These should not be counted manually; instead, the Detect Gap function can be used. This function automatically measures the pulses per revolution and detects the gap length. During gap length measurement, the RPM should remain as constant as possible.

The algorithm averages the machine speed a few samples before and after the gap. From this, the average speed around the gap is determined, and the number of missing pulses can be calculated.

Measurement results

The output channels of tape sensors are angle and frequency. The angle channel runs from 0° to 360°, while the frequency channel can be displayed either in RPM or in Hz.

On the recorder, the angle can be seen in the range of 0° to 360°. When the tape is rotating, the angle value increases, and when the zero pulse is detected, the value resets to 0. The frequency channel is displayed in RPM.

The RPM channel (green curve) is not a straight line because the rotor was not balanced. This demonstrates that the tape sensor can also be used for balancing rotating parts.

How Dewesoft Super Counter works?

Counters are primarily used for measuring RPM and the angle of rotating machines. Dewesoft SuperCounters operate on a 102.4 MHz internal time base at all times, independent of the current sample rate.

In comparison to a standard counter, which only outputs whole numbers (e.g., 1, 1, 2, 2, 3, 4) one sample later, DewesoftX can extract precise values such as 1.37, 1.87, or 2.37—fully synchronized in both time and amplitude. This is achieved by measuring the exact time of the rising edge of the signal with an additional counter.

Dewesoft supports a wide range of sensors, including:

Encoders with 1, 2, or 3 tracks (A, B, and Z reset signal).

Linear pulses and pulse encoder

With an optical tacho probe (1 pulse per revolution) and a reflective sticker, both angle and RPM can be calculated.

The typical automotive sensor is a gear-tooth sensor with missing teeth (e.g., 60-2) or double teeth. Other supported types include CDM, CDM with zero, and CDM with TRG.

| Required hardware | DEWE-43, Sirius ACC+, MULTI, STG+, STGM+ |

| Required software | Any version |

| Setup sample rate | At least 1 kHz |

Frequency/Super-Counter mode offers many advantages over traditional counter measurements.

The main limitation of traditional counters is that the counter value is latched only at the sample rate interval. As a result, only discrete values are available at each sample. Since SuperCounters can determine the exact position of the pulse between two samples, two key calculations are possible:

The exact interpolated position of the counter at the sample point.

The exact frequency of the pulses.

So, how does this mode work?

The hardware configuration is as follows: a signal (for example, from an encoder as shown in the example below) is connected to CNT0.

Next, let’s set up the channels. For SuperCounter and frequency measurement, two counters are required. Another limitation is that the counter channel must be set as an event counter.

The counter should be configured to Event Counting and Basic Encoder Counting, and then the Advanced Counter Mode option must be enabled. Once selected, the counter pair is automatically assigned, providing both an exact count and an exact frequency as calculated output channels. The Raw_Count and Raw_EdgeSep values are intended for advanced use only, as they represent the raw data directly from the counters.

In Image 86, we can see Source0, displayed as a digital line (purple) in the upper graph. In the lower graph, the orange curve represents the normal counter (raw counter values), which increases step by step at each sample. Meanwhile, the white curve represents the SuperCounter, where values are interpolated not only between counts but also between samples.

Example: Set the signal frequency from half of the sampling rate up to 50% higher than the sampling rate. With the normal counter, the output will remain constant for one sample, then jump, remain constant again, or jump by two values. The result is poor accuracy. In contrast, when using the SuperCounter, the values are perfectly aligned with the input signal, as shown in the example below. Additionally, the frequency measurement remains correct.

SuperCounter mode is particularly useful during the run-up and run-down of a test machine, where both the SuperCounter and frequency measurements provide highly accurate results. This method is the recommended approach for measuring advanced DSA features such as order tracking, torsional vibration, and rotational vibration.

How to setup a sensor measurement?

| Required hardware | DEWE-43, Sirius ACC+, MULTI |

| Required software | Any version |

| Setup sample rate | At least 1 kHz |

The SuperCounter mode is also used in a special counter mode called Sensor Mode (selected from the Basic Application drop-down menu). This mode allows the direct use of digital speed and position sensors as defined in the Counter Sensor Editor. Supported sensor types include rotary encoders, linear encoders, CDM sensors (angle sensors with zero reference), gear-tooth sensors with missing or double teeth, and tacho probes.

To configure, simply select the appropriate sensor from the Sensor Type drop-down menu. If the sensor has not yet been defined, click the ellipsis button (…) on the right side to open the Counter Sensor Editor, where new sensors can be defined. Sensors configured in this way always operate in SuperCounter mode, providing exact frequency and angle measurements.

One key benefit of using defined sensors is that scaling is handled automatically, eliminating the need for manual adjustment. Additional options are also available. For example, when using an encoder, you can select the Encoder Mode (X1, X2, or X4) and choose whether to enable Encoder Zero.

If Zero is used, a message will indicate how many pulses are detected between two zero points. This serves to inform the user of possible setup or connection errors (as shown in Image 88).

For the CDM sensor, the only special setting is the counting direction. By default, the CDM sensor counts up, but this option allows the direction to be reversed if needed.

The tacho and gear-tooth sensors have no special settings; their behavior depends entirely on how they are configured in the sensor definition.

How to measure a steering wheel?

We will examine two typical automotive applications: steering wheel measurements and wheel speed sensing.

| Required hardware | DEWE-43, Sirius ACC+, MULTI |

| Required software | Any version |

| Setup sample rate | At least 1 kHz |

Steering wheel measurement

In this case, a measurement steering wheel equipped with a quadrature encoder is used to capture both the angular position and angular velocity of the steering wheel during test drives. The quadrature encoder in our example has a resolution of 1800 pulses per revolution.

Channel setup

For Counter Mode, select the Sensor (encoder, CDM, tacho, etc.) from the Basic Application drop-down menu to decode signals from the quadrature encoder. Then, choose the appropriate sensor (e.g., Encoder – …) from the Sensor Type drop-down menu.

In Encoder Mode, the resolution of the angle measurement can be set. In this example, X1 is used, so the counter outputs 1800 pulses per revolution. X2 would output 3600 pulses per revolution, and X4 would output 7200 pulses per revolution. It is recommended to use an Input Filter (100 ns in this case) to prevent measurement errors caused by jitter or signal spikes. The quadrature encoder typically has three signals, but only Signal A and Signal B are required for this application.

It is important not to enable Encoder Zero if Signal Z is connected to the counter input; otherwise, a jump in the frequency channel may occur, and the manual zero-point definition could be lost. The preferred approach is to select the sensor from the predefined list, where scaling is handled automatically. In this case, Encoder Zero should be deselected, and Reset on Start Measure should also remain deselected to preserve the initial zero-point correction.

The first output is the angle, where units can be selected as degrees (alternatively, revolutions or counts). The second output is the frequency, which is already scaled in RPM or Hz.

Zero-point definition

After all channel setup settings are configured, the steering wheel must be set to zero at a specific steering angle. In most cases, the steering angle is defined as zero when the car is driving straight ahead. Zero-point definition can be performed by pressing Reset in the channel setup. This sets the steering angle to zero at the current steering wheel position.

A horizontal test track is recommended for zero-point definition to avoid steering angle offset errors. It is very important that Reset on Start Measure is not selected; otherwise, the counter value will be set to zero at every measurement, causing the zero-point definition to be lost.

The figure below shows the measurement results of the steering wheel.

How to measure with wheel speed sensor?

A wheel speed sensor or vehicle speed sensor is a type of tachometer. It is used for high-precision measurement of wheel speeds and rotations during test drives. Traveled distance and speed can also be measured, but this requires knowledge of the dynamic wheel radius. However, the dynamic wheel radius depends on the operating state of the wheel, including road conditions, driving conditions, cornering ability, tire pressure, and other factors. For this reason, precise distance measurement using dynamic wheel radius scaling is not recommended. Instead, solutions such as GPS (e.g., VGPS) or radar/optical sensors are preferred.

To configure the wheel sensor, the channel setup must be defined. Since this sensor is not included as a standard in DewesoftX, it must be created using the Counter Sensor Editor.

After the sensor is created, it only needs to be selected in the Sensor Editor under the Sensor Type drop-down list.

The angle output can be set to revolutions, degrees, or counts. The frequency unit can be set to either Hz or RPM.

Once the counter setup is complete, the math channel setup for traveled distance and velocity can be configured.

The first math channel is used to calculate displacement, which is determined using the dynamic wheel radius.

Equation for displacement:

A represents the angle channel output, which is a signal from the counter. R is the dynamic wheel radius. Displacement is expressed in meters [m].

In the figure below, the equation for displacement in DewesoftX is shown. In this example, the angle channel output is named 'CNT8/Angle', and the dynamic wheel radius is set to 0.25 m.

The second math channel is used to calculate the velocity of the car, using the same dynamic wheel radius as in the displacement calculation.

Equation for velocity:

F represents the frequency channel output, which is a signal from the counter, and R is the dynamic wheel radius. Velocity is expressed in meters per second [m/s].

In the figure below, the equations for velocity in DewesoftX are shown. In this example, the frequency channel output is named 'CNT8/Frequency'.

Measured and calculated channels are available in real time, without requiring any additional hardware or wiring. The figure below shows the measurement results from the wheel sensor.

How to transform time domain data into angle domain data?

Rotating machinery measurements are related to both the angular and time domains. A correct transformation of collected data from the time domain (accelerometers, pressure sensors, etc.) to the angular domain (encoders, inductive sensors, etc.) is essential. By using the device’s internal clocking, we benefit from access to both:

Time-domain data (FFT of vibrations, CAN bus data, voltages, currents, etc.)

Angular-domain data (harmonic components, pressure/position relationships, etc.)

In this case, we are interested in analyzing the combustion engine of a car to improve efficiency. The task is to measure the position of maximum pressure, which is related to the position of the piston in the cylinder rather than the measurement time. Since we know the volume of a cylinder and can measure pressure, it is best to relate the work to the piston’s position in the cylinder. This can be achieved by measuring one additional parameter—the angle of the main shaft.

Let’s look at an example. We measured power (red signal) and angle (blue signal) in the time domain, with many cycles recorded. The angle increases from 0 to 359 degrees and then resets to 0.

Now we want to observe the power in the angular domain. For this, we use the math function called Time-to-Vector Transform.

The input channel is power, and the reference channel is the angle (ranging from 0 to 359 degrees). We will calculate the minimum, maximum, and average values.

On the XY recorder, all cycles can be displayed together by selecting angle as the X-axis and power as the Y-axis.

If we want to display only the average (blue), minimum (green), or maximum (red) curve, we use a 2D graph.

Page 1 of 21