Sound Level Measurement

Class 1 Sound Level Meter for Sound and Noise Level Measurement

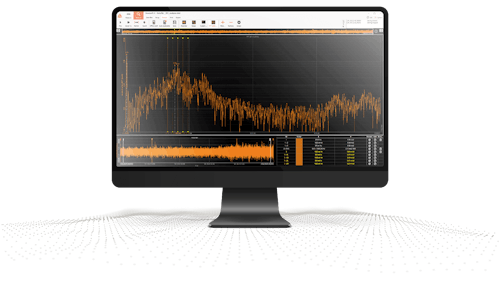

Major manufacturers all around the world rely on Dewesoft NVH measurement systems for optimizing the interior and exterior noise, vibration, and harshness characteristics of their vehicles. Our DAQ systems offer full support for microphones and accelerometers for measuring and analyzing NVH data, all compliant with international standards and supported by calibration services. High bandwidth recording is combined with advanced software tools, including FFT analysis, order tracking, modal analysis, sound quality/level/power/intensity, and octave band analysis. Specific tests like pass-by noise, RT60 reverberation time, brake noise, and human-body vibration analysis are also supported.

Browse products

Class 1 Sound Level Meter for Sound and Noise Level Measurement

Sound intensity level solution fully compliant with ISO standards

Applied psychoacoustics and sound engineering

Sound power level measurement solution according to ISO standards

Octave band frequency analysis solution for sound and noise

Vibration and frequency analysis with a Fast Fourier transform

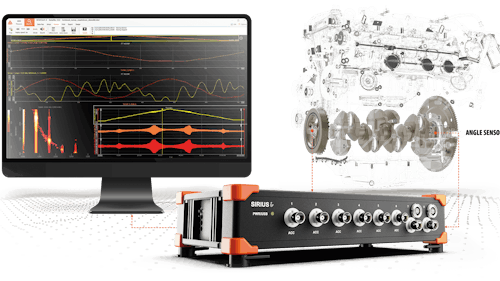

Measure angular vibration of the rotating shafts

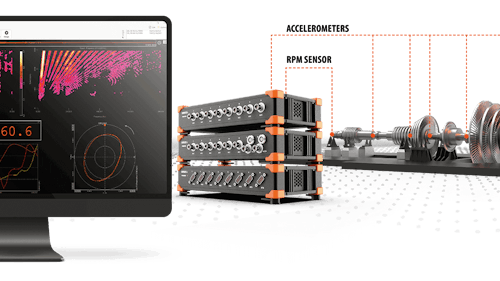

Noise and vibration analysis for rotating and reciprocating machinery

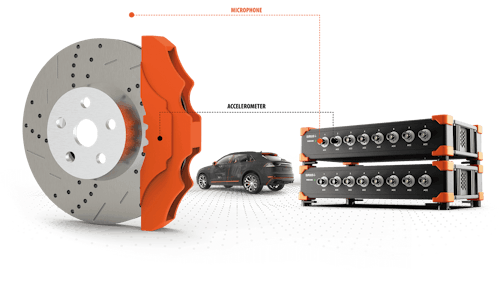

Detect and track brake noise according to VDA 303 guideline

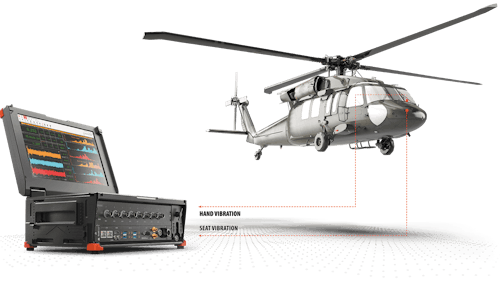

Whole-body and hand-arm vibration measurement

Structural, Electrical, NVH, and Flight Testing Solutions

Instrumentation for complete testing of jet engines

Noise, vibration, and harshness (NVH), also known as noise and vibration, is the study and modification of the noise and vibration characteristics of vehicles such as cars and trucks. While we can measure noise and vibration, harshness is a more subjective quality and is measured either via jury evaluations or with analytical tools that can provide results reflecting human subjective impressions (psychoacoustics).

NVH can be tonal such as engine noise (or powertrain noise), or broadband, such as road noise or wind noise. Basically, it is everything that drivers or passengers can either hear and feel from a vehicle while driving. A few such examples are wind noise, road noise, bumps from the suspension, or vibrations from the engine.

Noise is unwanted sound or unwanted disturbance in an electronic signal. Acoustic noise is energy transmitted to the air that causes an audible disturbance. Tools such as acoustic intensity mapping and combustion/mechanical noise separation can be used to identify the best method of noise reduction.

Vibration is an oscillation that causes noise and disturbance. Vibration is generally of concern due to its physical effects which can cause disturbance to people, disruption in electrical systems, and failure or breakdown in mechanical systems. Shakers and controllers are techniques used to test vibration issues.

Harshness is generally used to describe the severity and discomfort associated with both vibration and noise. It is a qualitative system based on desired characteristics rather than on quantifiable measurements.

NVH testing is widely used in the automotive industry for the reduction, design, and quality assurance of interior and exterior vehicle noise and vibration. The process usually takes place during vehicle development mainly in passenger cars, trucks, and other similar vehicles.

NVH testing involves subjecting a full vehicle, component, or subassembly to vibrations at different frequencies, as a means of determining mode shapes and isolating buzzes, squeaks, and rattles. Typical instrumentation used to measure NVH includes microphones, accelerometers, force gauges, and load cells. Component and subassembly NVH tests are most commonly performed using a vibration shaker, while entire vehicles are usually tested on proving grounds or road simulator testbeds.

Many NVH facilities have semi-anechoic chambers and rolling road dynamometers. Typically, signals are recorded by a data acquisition system directly to a hard disk via sensors and an ADC converter (analog-to-digital converter), and a suitable signal conditioner.

Improving NVH can be achieved by reducing the source strength, interrupting the noise or vibration path, or by absorption of the noise or vibration energy. Techniques used to help identify NVH include part substitution, modal analysis, rig squeak and rattle tests (complete vehicle or component/system tests), lead cladding, acoustic intensity, transfer path analysis, and partial coherence.

Case Studies

To improve the vibrational comfort of a 1960s vehicle gem, a Lancia Flaminia, we did some vibrational testing and analysis. Read the article to learn how.

Case Studies

This case study presents a year-long vibration-based monitoring campaign of gearbox health on an offshore Crew Transfer Vessel using Dewesoft hardware and software. The research aims to enable predictive maintenance amid harsh marine conditions, using accelerometers, temperature sensors, and a gyroscope installed on one of the vessel's twin hulls. Data is collected via a DEWE-43A unit, stored externally, and processed in DewesoftX with FFT analysis for early fault detection.

Case Studies

University of Applied Sciences in Frankfurt sought to simplify vibration and noise measurement for car design. Dewesoft's solution allowed for synchronized data acquisition and various exports from one measurement file, reducing interactions and testbed hours.

Case Studies

See how the Dewesoft sound intensity solutions and data acquisition system helped to do the automated measurement of the sound intensity on Bobcat loaders.

Case Studies

Dewesoft SIRIUS system was used for in-vehicle and MTS rig testing on potential solutions for field issues on the Hoods of some trucks.

Case Studies

Dewesoft data acquisition systems are used to measure diesel generators for ISO 8528-1:2005 certification standards for sound, vibration, and temperature.

Case Studies

See how the Dewesoft team performed exhaust noise testing and calculated vehicle RPMs based on the sound measurements at the Formula Student racing event.