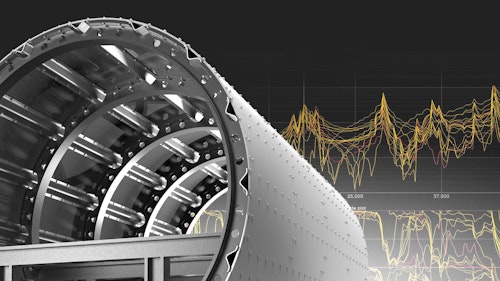

Aerospace

From wind tunnels to launch pads, Dewesoft DAQ systems support flight, telemetry, and bus data testing—trusted by NASA, ESA, SpaceX, Airbus, Embraer and more for mission-critical aerospace applications.

Dewesoft is a global leader in test and measurement technology, trusted by engineers, scientists, and innovators across a wide range of industries and application areas. Our award-winning data acquisition (DAQ) systems deliver unmatched versatility, precision, and ease of use.

Whether you’re developing the next generation of vehicles, launching spacecraft, maintaining energy infrastructure, or ensuring quality on the production line, Dewesoft empowers you with reliable data—wherever your work takes you. From R&D and testing to monitoring and control, our DAQ solutions are built to perform in any environment—from the factory floor to a suspension bridge.

Dewesoft’s versatile data acquisition systems support a broad range of applications across industries—from automotive and aerospace to power, civil engineering, and manufacturing. This section helps you explore the full scope of what our technology can handle. You can browse by application area, industry, or specific use case—whichever makes the most sense for your project. We’ve organized this content to make it easy for you to discover relevant solutions—whether you’re looking to solve a specific measurement challenge or just exploring what’s possible with Dewesoft.

From wind tunnels to launch pads, Dewesoft DAQ systems support flight, telemetry, and bus data testing—trusted by NASA, ESA, SpaceX, Airbus, Embraer and more for mission-critical aerospace applications.

Trusted by virtually every OEM, Dewesoft DAQ systems support vehicle testing from combustion to durability—capturing synchronized sensor, bus data, GNSS, and video data in lab and road environments.

Dewesoft DAQ systems monitor bridges, tunnels, and skyscrapers worldwide—delivering synchronized, rugged, and scalable measurements for structural safety, SCADA, and cloud integration.

Dewesoft DAQ systems empower the next generation of engineers and researchers with hands-on experience in real-world measurements—essential for mastering sensor technology and data analysis.

Dewesoft offers precise, synchronized DAQ for testing e-drives, batteries, inverters, and hybrid systems—ideal for lab, field, and EOL testing in advanced electrified vehicle development

Dewesoft DAQ systems, trusted by CAT, John Deere, Komatsu, Volvo, and many others deliver reliable testing in harsh conditions—ideal for heavy machinery, capturing synchronized data like strain, pressure, vibration, temperature, and more.

ABB, Atlas Copco, Vale, and others trust Dewesoft DAQ systems for factory and machine monitoring—offering IIoT-ready, EtherCAT-based solutions that integrate with SCADA, ERP, and cloud systems.

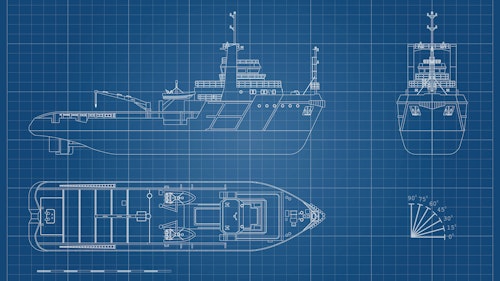

Dewesoft DAQ systems test engines, shafts, power, and structural integrity on vessels of all sizes—ideal for R&D, retrofits, and modal analysis, even in extreme marine conditions.

Dewesoft DAQ systems ensure precise power and efficiency analysis—measuring voltage, current, temperature, frequency, vibration, and more in sync, replacing multiple tools with one high-performance solution.

From subways to freight trains, Dewesoft DAQ systems test engines, power systems, NVH, and infrastructure—ensuring safety and performance across rail vehicles, tracks, tunnels, and bridges.

Dewesoft offers a complete solution for acoustic testing—covering sound level, power, quality, and intensity measurements with full microphone support and intuitive software for reliable, standards-based analysis.

Dewesoft power analyzers combine power, energy, scope, and FFT in one system—measuring up to ±2000 V at 0.03% accuracy, with Class A PQ compliance, multi-phase support, and rich, customizable visualizations.

Dewesoft DAQ systems support aerospace testing from ground to launch—covering structural, acoustic, and power measurements, plus full integration with flight buses, telemetry, and control systems.

Dewesoft offers a complete and affordable NVH testing solution—trusted by leading manufacturers for analyzing noise, vibration, and harshness with full sensor support, advanced analysis tools, and standards compliance.

Dewesoft monitoring solutions support structural, industrial, and rotating machinery health—fully IIoT-ready with cloud access and seamless integration into SCADA, ERP, and existing infrastructure.

Dewesoft offers a unique all-in-one solution for testing rotating and reciprocating machinery—combining order tracking, orbit analysis, balancing, vibration, and power diagnostics in a single system.

Dewesoft DAQ systems offer flexible solutions for structural testing and durability analysis—from modal and fatigue testing on vehicles and aircrafts to health monitoring of bridges and buildings, in both lab and real-world environments.

Dewesoft DAQ systems power vehicle testing worldwide—syncing sensors, CAN, GPS, video, and more for drivetrain, NVH, durability, ADAS, and more. Rugged and portable, ideal for lab, bench, or in-vehicle use.

Dewesoft delivers a complete solution for vibration testing—supporting all sensor types and analysis methods, from FFT to orbit and order tracking, with powerful real-time tools and intuitive data visualization.

Dewesoft DAQ systems offer flexible data recording for any signal—supporting sensors, digital buses, video, and audio. Intuitive software enables fast setup, flexible storing, rich visualization, and powerful analysis.

Our proven solutions combine tightly knit hardware and software ... right out of the box. We follow all relevant industry standards and international norms when developing our hardware and software. There are standards that apply to automotive testing, acoustic testing, and power quality analysis. We combine our top-quality hardware with software that has been specifically written for each of these applications. Check our in-depth article about supported standards in Dewesoft measurement solutions.

Our subject matter expertise is the result of working directly with you - our customers – for decades. Our application engineers have the education and experience to ensure that there is strong and capable support behind every solution that we offer. Whether it’s in acoustics, automotive engineering, modal analysis, flight test telemetry, power, and energy, or general data recording, we are here.

The third decade of working closely with engineers in different R&D industries has brought our solutions to the next level. We are equipping engineers with unique and innovative instrumentations. Our solutions are used in the world's most advanced testing labs and proving grounds. Dewesoft is a trusted global partner with today's most progressive brands.

Our specialty has always been developing cutting-edge products and services to create turn-key data acquisition solutions that fit perfectly customers' testing demands in the lab, test bench, or on the field.

We entered the structural health monitoring market by introducing some unique products. Our monitoring solution includes sensors, signal conditioning amplifiers, data acquisition software, a modern database for long-term storage, and clients for viewing and analyzing the monitored data.

With highly skilled application engineering and support teams, you can always consult us and rely on our know-how. We have instrumented the world's biggest bridge and some of the oldest and most impressive buildings out there.

End-of-line testing is an important process in production to assure the great quality of your products. The flexibility of our products and solutions makes them easily adaptable for quality control and validation testing. Our software can be automated for operators to allow them fast execution and repetition of the tests.

From industrial process control to end-of-line testing applications, Dewesoft provides complete solutions ranging from sensors to instrumentation. Our solutions and products comply with current standards and also offer Industry 4.0 integration options.

Case Studies

At the University of Ljubljana, four servo motors were tested using Dewesoft tools to compare accuracy, efficiency, and thermal stability under loaded and unloaded conditions. Measurements of rotation, temperature, and power showed the Turnigy DMC 809 as the best performer, with consistent accuracy, minimal heating, and low power use, while the Waveshare WS-SG90 proved least reliable for demanding applications.

Case Studies

Skyward Experimental Rocketry, a student team from Politecnico di Milano, developed and tested Aeneas, Italy’s first bi-liquid rocket engine. Using Dewesoft’s IOLITE platform, they built a precise data acquisition and control system to ensure safe static fire tests. The project advances hands-on rocketry education and paves the way for next-gen 3D-printed, regeneratively cooled engines.

Case Studies

The UniNa Corse Racing Team from the University of Naples developed and validated a brake disc model for their first fully electric Formula SAE car, Nura. Using Dewesoft data acquisition and Radio6ense sensors, they compared CFD simulations with real track tests to analyze thermal behavior. This allowed them to refine the brake system design for improved safety, efficiency, and performance in competition.

Case Studies

The AQUILO Rocket Team at Inholland University tested S-type load cells in tension and compression to improve rocket thrust measurement accuracy. Using Dewesoft’s SIRIUS DAQ and software, they evaluated 200 kg and 1000 kg cells, finding compression more accurate—by 76.9% and 40.9% respectively. The study highlights how load cell capacity and force direction affect data reliability, guiding future horizontal test stand designs.

Case Studies

Electric scooters rely on compact, efficient BLDC motors whose performance depends heavily on supply voltage. A study at Tallinn University of Technology utilized Dewesoft Power Analyzer tools to investigate the impact of voltage on output power and efficiency. Results showed that an operating range of approximately 45 V is optimal, delivering peak efficiency and stability. These findings can help improve scooter design, enhance battery life, and contribute to global energy savings.

Case Studies

Team H2politO from Politecnico di Torino conducted an experimental study on the tire and drivetrain behavior of their hydrogen prototype IDRAzephyrus. Using Dewesoft DAQ systems and RFID temperature sensors, they measured cornering stiffness, slip, and thermal response. The insights improve vehicle modeling, efficiency, and race strategy for the Shell Eco-Marathon, where minimizing fuel use is key.

Case Studies

The University of Pisa’s E-Team Squadra Corse partnered with Dewesoft and Radio6ense to enhance their Formula SAE electric car. Using high-frequency data acquisition and RFID-based thermal mapping, the team optimized inverter control parameters and validated the battery’s thermal model. These insights improved powertrain reliability, safety, and performance under demanding race conditions.

Case Studies

Bearings are vital in industrial machinery, and their early fault detection prevents costly downtime. This study shows how Dewesoft vibration analysis tools, paired with high-sensitivity sensors and advanced signal processing, enable precise monitoring of bearing health. By integrating machine learning with high-resolution data acquisition, it demonstrates a powerful approach to predictive maintenance and Industry 4.0.

Case Studies

Team PoliTOcean from the Polytechnic University of Turin developed a test bench to control and monitor eight underwater thrusters using PWM. With Dewesoft’s SIRIUS-HD-16xLV and DewesoftX, they measured voltage, current, and waveforms in real time, identifying power delivery issues linked to DC/DC converters. The campaign validated their PCB design and laid the groundwork for future AI-driven thruster performance modeling.

Case Studies

Identifying unlabeled circuit breakers without shutting off power is a major challenge in critical facilities. This project introduces a pulse-based method using MOSFET-based SSRs, flux-gate magnetic sensors, and a Dewesoft SIRIUS DAQ system to detect live breakers. Early tests show promise for precise, non-intrusive identification, though further refinement is needed for reliability in noisy real-world environments.

Case Studies

The AQUILO Rocket Team from Inholland University conducted a static fire test of their PB-51C solid rocket motor, using Dewesoft’s DAQ systems to measure thermal and thrust data. Results confirmed safe casing temperatures but revealed unexpected thrust spikes, likely caused by ignitor holder failure. These findings will guide design improvements for their upcoming AQUILO IX rocket, targeting EuRoC 2026.

Case Studies

Faraday Rocketry UPV upgraded its static fire test setup with Dewesoft SIRIUS hardware and DewesoftX software, enabling precise, real-time measurement of thrust, temperature, and vibration for student-built rocket motors. The new system improved accuracy, reduced complexity, and matched simulation results, certifying the motor’s flight readiness and boosting the team’s future development capabilities.

Case Studies

Researchers at FH Joanneum retrofitted a metal-cutting band saw with Dewesoft sensors to monitor vibrations, sound, and temperature, successfully digitizing an old machine for real-time condition monitoring. This hands-on setup helps detect tool wear, improves efficiency, and now serves as a practical training tool for students and industry partners in smart manufacturing.

Case Studies

A student project tested the reliability of automated greenhouse doors controlled by temperature using an Arduino system and the Dewesoft DEWE-43A data acquisition device. The system showed stable operation and effective temperature-based responses, with detailed sensor analysis identifying areas for improvement in obstacle detection and mechanical reliability. Future upgrades include sensor enhancements and IoT integration for remote diagnostics.

Case Studies

Swegon implemented a real-time snow load monitoring system using Dewesoft strain gauge technology to prevent roof collapses in its Swedish production hall. The system tracks structural strain, sends alerts when critical thresholds are reached, and ensures timely snow removal. It combines synchronized data acquisition, visualization, and alarms to enhance safety and maintain operational continuity.

Case Studies

This case study presents a year-long vibration-based monitoring campaign of gearbox health on an offshore Crew Transfer Vessel using Dewesoft hardware and software. The research aims to enable predictive maintenance amid harsh marine conditions, using accelerometers, temperature sensors, and a gyroscope installed on one of the vessel's twin hulls. Data is collected via a DEWE-43A unit, stored externally, and processed in DewesoftX with FFT analysis for early fault detection.

Trusted by the world’s most progressive brands