创新的数据采集 (DAQ) 应用。

德维软件公司是一家 测试与测量技术的全球领导者我们的数据采集 (DAQ) 系统深受各行各业和应用领域的工程师、科学家和创新者的信赖。我们屡获殊荣的数据采集 (DAQ) 系统具有无与伦比的多功能性、精确性和易用性。

无论您是在开发下一代汽车、发射航天器、维护能源基础设施,还是在生产线上确保质量,Dewesoft 都能为您提供可靠的数据,无论您的工作在哪里。从研发和测试到监测和控制,我们的 DAQ 解决方案可在从工厂车间到吊桥的任何环境中运行。

浏览应用类别

Dewesoft 的多功能数据采集系统支持从汽车、航空航天到电力、土木工程和制造业等各行各业的广泛应用。本节将帮助您全面了解我们的技术。您可以通过以下方式浏览 应用领域, 产业或 具体用例-无论哪种方式对您的项目最有意义。我们对这些内容进行了整理,以便您轻松找到相关的解决方案--无论您是希望解决特定的测量难题,还是只是探索 Dewesoft 的可能性。

按行业分类

重型机械

Dewesoft DAQ 系统深受 CAT、John Deere、Komatsu、Volvo 等公司的信赖,可在恶劣条件下提供可靠的测试,是重型机械的理想之选,可捕获应变、压力、振动、温度等同步数据。

工业的

ABB、阿特拉斯-科普柯(Atlas Copco)、淡水河谷(Vale)等公司都信赖 Dewesoft DAQ 系统,将其用于工厂和机器监控--提供可与 SCADA、ERP 和云系统集成的 IIoT 就绪型、基于 EtherCAT 的解决方案。

按应用领域

车辆测试

Dewesoft DAQ 系统为全球车辆测试提供动力--同步传感器、CAN、GPS、视频等,用于动力传动系统、NVH、耐久性、ADAS 等。坚固耐用、便于携带,是实验室、工作台或车内使用的理想之选。

符合行业标准和规范的解决方案

我们成熟的解决方案将硬件和软件紧密结合......开箱即用。在开发硬件和软件时,我们遵循所有相关行业标准和国际规范。这些标准适用于汽车测试、声学测试和电能质量分析。我们将一流的硬件与专门为这些应用编写的软件相结合。查看我们的 关于支持的标准的深度文章在 Dewesoft 测量解决方案中。

值得信赖的学科专业知识

我们的专业知识是几十年来与客户直接合作的结晶。我们的应用工程师拥有丰富的教育背景和经验,确保我们提供的每一个解决方案都能得到强有力的支持。无论是声学、汽车工程、模态分析、飞行测试遥测、电力和能源,还是普通数据记录,我们都能为您提供支持。

研发测试工具

在与不同研发行业的工程师密切合作的第三个十年中,我们的解决方案更上一层楼。我们为工程师配备了独一无二的创新仪器。我们的解决方案被用于世界上最先进的测试实验室和试验场。Dewesoft 是当今最先进品牌值得信赖的全球合作伙伴。

我们的专长一直是开发尖端产品和服务,提供交钥匙数据采集解决方案,完美满足客户在实验室、测试台或现场的测试需求。

监测工具

我们通过推出一些独特的产品进入了结构健康监测市场。我们的监测解决方案包括传感器、信号调节放大器、数据采集软件、用于长期存储的现代化数据库以及用于查看和分析监测数据的客户端。

我们拥有技术精湛的应用工程和支持团队,您可以随时向我们咨询,并信赖我们的专业知识。我们已经为世界上最大的桥梁和一些最古老、最令人印象深刻的建筑安装了仪器。

质量控制工具

生产线末端测试是确保产品质量的重要生产流程。我们的产品和解决方案非常灵活,可轻松用于质量控制和验证测试。我们的软件可为操作员提供自动化服务,使他们能够快速执行和重复测试。

从工业过程控制到终端测试应用,Dewesoft 提供从传感器到仪器仪表的完整解决方案。我们的解决方案和产品符合现行标准,并提供工业 4.0 集成选项。

浏览最近的案例研究

案例研究

Comparing and Evaluating Servo Motor Accuracy, Efficiency, and Thermal Stability

At the University of Ljubljana, four servo motors were tested using Dewesoft tools to compare accuracy, efficiency, and thermal stability under loaded and unloaded conditions. Measurements of rotation, temperature, and power showed the Turnigy DMC 809 as the best performer, with consistent accuracy, minimal heating, and low power use, while the Waveshare WS-SG90 proved least reliable for demanding applications.

案例研究

Data Acquisition and Control for Testing Italy’s First Bi-Liquid Rocket Engine

Skyward Experimental Rocketry, a student team from Politecnico di Milano, developed and tested Aeneas, Italy’s first bi-liquid rocket engine. Using Dewesoft’s IOLITE platform, they built a precise data acquisition and control system to ensure safe static fire tests. The project advances hands-on rocketry education and paves the way for next-gen 3D-printed, regeneratively cooled engines.

案例研究

Testing and Validation of a Brake Disc Model for a Formula SAE Car

The UniNa Corse Racing Team from the University of Naples developed and validated a brake disc model for their first fully electric Formula SAE car, Nura. Using Dewesoft data acquisition and Radio6ense sensors, they compared CFD simulations with real track tests to analyze thermal behavior. This allowed them to refine the brake system design for improved safety, efficiency, and performance in competition.

案例研究

Testing Load Cell Tension and Compression for Accurate Rocket Thrust Measurement

The AQUILO Rocket Team at Inholland University tested S-type load cells in tension and compression to improve rocket thrust measurement accuracy. Using Dewesoft’s SIRIUS DAQ and software, they evaluated 200 kg and 1000 kg cells, finding compression more accurate—by 76.9% and 40.9% respectively. The study highlights how load cell capacity and force direction affect data reliability, guiding future horizontal test stand designs.

案例研究

Optimizing Electric Scooter BLDC Motor Efficiency Using Dewesoft Power Analyzer

Electric scooters rely on compact, efficient BLDC motors whose performance depends heavily on supply voltage. A study at Tallinn University of Technology utilized Dewesoft Power Analyzer tools to investigate the impact of voltage on output power and efficiency. Results showed that an operating range of approximately 45 V is optimal, delivering peak efficiency and stability. These findings can help improve scooter design, enhance battery life, and contribute to global energy savings.

案例研究

Experimental Analysis of Tire Behavior on a Hydrogen Vehicle

Team H2politO from Politecnico di Torino conducted an experimental study on the tire and drivetrain behavior of their hydrogen prototype IDRAzephyrus. Using Dewesoft DAQ systems and RFID temperature sensors, they measured cornering stiffness, slip, and thermal response. The insights improve vehicle modeling, efficiency, and race strategy for the Shell Eco-Marathon, where minimizing fuel use is key.

案例研究

Optimizing Inverter Control Parameters and Thermal Mapping of a Formula SAE Car

The University of Pisa’s E-Team Squadra Corse partnered with Dewesoft and Radio6ense to enhance their Formula SAE electric car. Using high-frequency data acquisition and RFID-based thermal mapping, the team optimized inverter control parameters and validated the battery’s thermal model. These insights improved powertrain reliability, safety, and performance under demanding race conditions.

案例研究

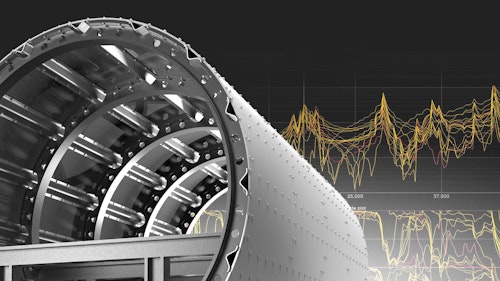

Bearing Fault Diagnosis Using Dewesoft Vibration Analysis Tools

Bearings are vital in industrial machinery, and their early fault detection prevents costly downtime. This study shows how Dewesoft vibration analysis tools, paired with high-sensitivity sensors and advanced signal processing, enable precise monitoring of bearing health. By integrating machine learning with high-resolution data acquisition, it demonstrates a powerful approach to predictive maintenance and Industry 4.0.

案例研究

Pulse Width Modulation Control and Monitoring on Test Bench for Underwater Thrusters

Team PoliTOcean from the Polytechnic University of Turin developed a test bench to control and monitor eight underwater thrusters using PWM. With Dewesoft’s SIRIUS-HD-16xLV and DewesoftX, they measured voltage, current, and waveforms in real time, identifying power delivery issues linked to DC/DC converters. The campaign validated their PCB design and laid the groundwork for future AI-driven thruster performance modeling.

案例研究

Load Circuit Breaker Identification in a Power Distribution Cabinet

Identifying unlabeled circuit breakers without shutting off power is a major challenge in critical facilities. This project introduces a pulse-based method using MOSFET-based SSRs, flux-gate magnetic sensors, and a Dewesoft SIRIUS DAQ system to detect live breakers. Early tests show promise for precise, non-intrusive identification, though further refinement is needed for reliability in noisy real-world environments.

案例研究

Static Fire Test of a Student-Built Rocket Engine

The AQUILO Rocket Team from Inholland University conducted a static fire test of their PB-51C solid rocket motor, using Dewesoft’s DAQ systems to measure thermal and thrust data. Results confirmed safe casing temperatures but revealed unexpected thrust spikes, likely caused by ignitor holder failure. These findings will guide design improvements for their upcoming AQUILO IX rocket, targeting EuRoC 2026.

案例研究

Data Acquisition for Rocket Engine Static Fire Test

Faraday Rocketry UPV upgraded its static fire test setup with Dewesoft SIRIUS hardware and DewesoftX software, enabling precise, real-time measurement of thrust, temperature, and vibration for student-built rocket motors. The new system improved accuracy, reduced complexity, and matched simulation results, certifying the motor’s flight readiness and boosting the team’s future development capabilities.

案例研究

Condition Monitoring of Metal-Cutting Machine

Researchers at FH Joanneum retrofitted a metal-cutting band saw with Dewesoft sensors to monitor vibrations, sound, and temperature, successfully digitizing an old machine for real-time condition monitoring. This hands-on setup helps detect tool wear, improves efficiency, and now serves as a practical training tool for students and industry partners in smart manufacturing.

案例研究

Testing the Reliability of Automated Greenhouse Doors

A student project tested the reliability of automated greenhouse doors controlled by temperature using an Arduino system and the Dewesoft DEWE-43A data acquisition device. The system showed stable operation and effective temperature-based responses, with detailed sensor analysis identifying areas for improvement in obstacle detection and mechanical reliability. Future upgrades include sensor enhancements and IoT integration for remote diagnostics.

案例研究

Real-Time Snow Load Monitoring on Industrial Roofs

Swegon implemented a real-time snow load monitoring system using Dewesoft strain gauge technology to prevent roof collapses in its Swedish production hall. The system tracks structural strain, sends alerts when critical thresholds are reached, and ensures timely snow removal. It combines synchronized data acquisition, visualization, and alarms to enhance safety and maintain operational continuity.

案例研究

Vibration-Based Health Monitoring of Gearboxes on Offshore Crew Transfer Vessel

This case study presents a year-long vibration-based monitoring campaign of gearbox health on an offshore Crew Transfer Vessel using Dewesoft hardware and software. The research aims to enable predictive maintenance amid harsh marine conditions, using accelerometers, temperature sensors, and a gyroscope installed on one of the vessel's twin hulls. Data is collected via a DEWE-43A unit, stored externally, and processed in DewesoftX with FFT analysis for early fault detection.

深受全球最先进品牌的信赖